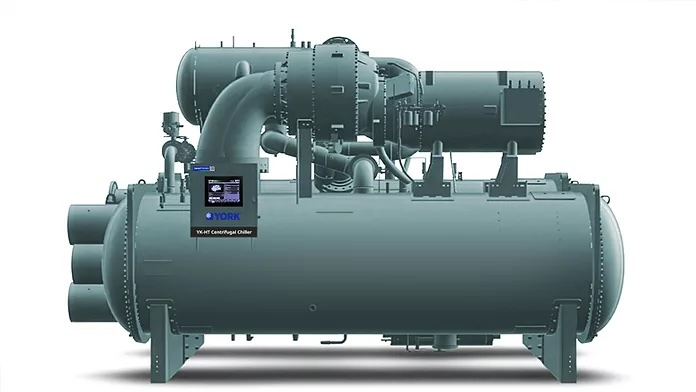

Johnson Controls has previewed the YORK YK-HT two-stage economized centrifugal chiller at AHR Expo 2026 in Las Vegas, positioning it for data centers and large industrial, pharmaceutical, and healthcare campuses. The company says the YK-HT’s high-lift compressor and extended operating range are designed to support closed-loop heat rejection with dry coolers instead of cooling towers, aiming to cut cooling-water use while expanding heat-pump and heat-recovery options.

Johnson Controls reports the YK-HT operates with condenser leaving fluid temperatures up to 165°F and up to 110°F of lift, which it says enables high-temperature operation from a single driveline. The company adds that this operating range supports heat-pump and heat-recovery applications, where reusing thermal energy “can offset more than 35 MMBtu per hour,” which it equates to “the heating demand of approximately 350 single-family homes per hour,” while lowering carbon emissions and reducing energy costs.

For data center deployments constrained by water and noise limits, Johnson Controls claims dry-cooler pairing can eliminate cooling-tower water consumption entirely. It gives an example that a typical 2,000-ton chiller operating in Las Vegas “consumes approximately 8 to 9 million gallons of cooling-tower water annually,” and says the YK-HT with dry coolers eliminates that water use. For large data centers, including “AI factories,” Johnson Controls also claims the YK-HT’s lift capability can enable “up to a 60% reduction in dry coolers” and enough fan-power reduction to lower onsite noise “by as much as 20 dBA.”

The company positions the YK-HT as a single packaged heating-and-cooling platform for large buildings, stating it can produce 44°F chilled water and 140°F hot water at the same time, which it describes as a normal heat-pump operating condition, while “delivering efficiency levels that exceed ASHRAE requirements.” Johnson Controls says this can remove the need for cascaded systems, extra electrical infrastructure, or major mechanical room redesigns. It also reports a “compact single-driveline design” that “cuts failure points by 50%,” along with “a footprint nearly 30% smaller than most alternatives” to help with legacy-space retrofits and reduce installation and service complexity amid skilled-labor shortages.

Other listed features include support for low-global-warming-potential refrigerants R-1234ze and R-515B; an integrated lubrication system; dual variable geometry diffuser control; a flash tank economizer; optional variable speed drives “for increased efficiency and BESS compatibility”; and “Smart Ready connectivity” for integration. Johnson Controls says testing occurs at the Johnson Controls Advanced Development and Engineering Center in New Freedom, Pennsylvania, and in Wuxi, China, and that the units are planned for global distribution with manufacturing in San Antonio, Texas, and Wuxi, China.

Source: Johnson Controls