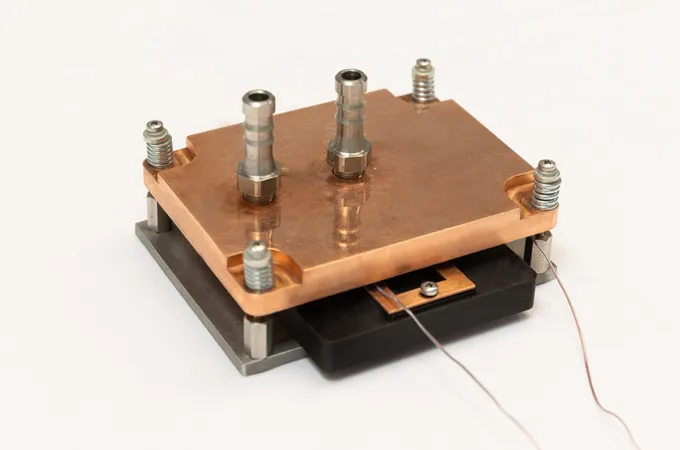

CoolIT Systems has announced successful testing of its single-phase Direct Liquid Cooling (DLC) coldplate, achieving effective thermal management for processors consuming up to 4000 W. This demonstration confirms the technology’s viability for cooling future high-wattage semiconductor platforms, particularly in data centers deploying AI processors rated beyond 1000 W Thermal Design Power (TDP).

In internal tests, CoolIT’s 4000 W coldplate captured more than 97% of generated heat from a 4000 W Thermal Test Vehicle (TTV) at a flow rate of 6 liters per minute (LPM)—equivalent to the semiconductor industry’s recommended rate of 1.5 LPM per kW for high-power chips. The test further demonstrated strong thermal performance even at lower flow rates.

CoolIT’s coldplate achieved an ultra-low thermal resistance under 0.009 °C/W while keeping the complete flow-loop pressure drop—including quick disconnects and fittings—to 8 PSI. The proprietary Split-Flow design used in these coldplates is already deployed across multiple generations by leading global server manufacturers, offering 30% improved thermal and flow performance compared to standard coldplates, along with targeted cooling capability for localized hot spots.

Single-phase DLC technology dissipates heat effectively by circulating water or a water-glycol solution through direct-contact coldplates mounted onto semiconductor chips. According to CoolIT, this method is currently the industry’s most mature and widely adopted liquid cooling solution for high-wattage microprocessors, particularly in data center environments handling intensive workloads such as AI training and inference.

“CoolIT continues to lead the industry in performance,” said Kamal Mostafavi, VP of Engineering. “We are thrilled to show silicon leaders that single-phase DLC will continue to be a key enabling technology with demonstrated capability for up to 4000W processors.”

Source: CoolIT Systems