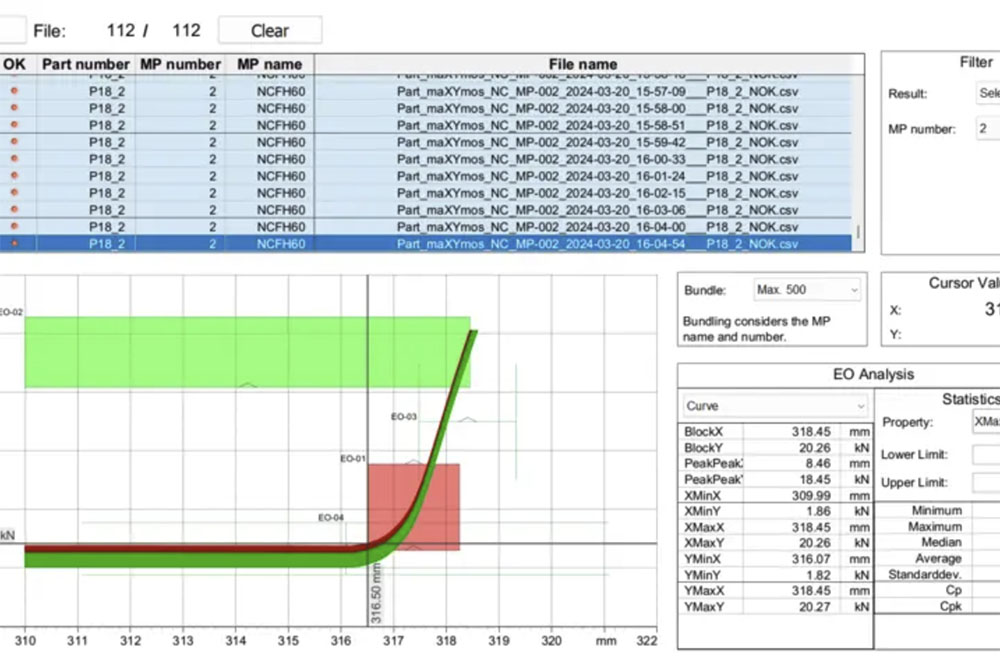

Kistler has introduced the maXYmos Analyzer PC software, designed as the final link in its process monitoring measurement chain. The software enables rapid analysis and visualization of measurement curves collected during production, such as force-displacement data from joining applications. The release aims to help engineers detect component irregularities and optimize production by providing a streamlined workflow for measurement curve evaluation, directly addressing data-driven production optimization and quality assurance tasks.

The maXYmos Analyzer is built on Kistler’s jBEAM measurement data analysis platform. It allows users to zoom, compare, filter, and analyze measurement curves either in real time or during post-process reviews. Technical functionality includes automatic calculation of Statistical Process Control (SPC) metrics such as Cp and CpK for selected batches of curves. The software also supports interactive Key Performance Indicator (KPI) monitoring, along with statistical and trend analysis tools, which Kistler says can inform operational decision-making in process optimization scenarios.

For data center and manufacturing environments focusing on automation, joining, and assembly, maXYmos Analyzer addresses applications that rely on precise measurement data for quality assurance. It is compatible with maXYmos NC (for Kistler joining systems version 1.7 and later), maXYmos TL (model 5877B from version 1.7), and maXYmos BL (from model 5867C onward). Kistler notes that a free trial version is available.

Kistler reports that with the addition of the maXYmos Analyzer (model 2850A) PC software, users can now implement a complete measurement and analysis workflow covering assembly sensors, process monitoring systems, and electromechanical joining systems, all provided by Kistler.

Source: Kistler