KAYTUS has announced it completed a 100-cabinet, high-density liquid-cooled AI data center buildout in Europe in four months, using what it describes as an integrated turnkey service that combines deployment and commissioning. KAYTUS says the approach cut deployment time by up to 80% versus traditional liquid-cooled data center delivery models and improved overall system performance by 20% after performance testing and tuning.

According to KAYTUS, the customer is a European infrastructure unicorn that provides compute, storage, and networking services to e-commerce, fintech, and digital media customers. KAYTUS attributes the accelerated timeline to a “cabinet-as-a-system” delivery model that shifts system integration and validation work from the site to the factory, reducing the amount of on-site secondary-loop liquid-cooling construction and commissioning required.

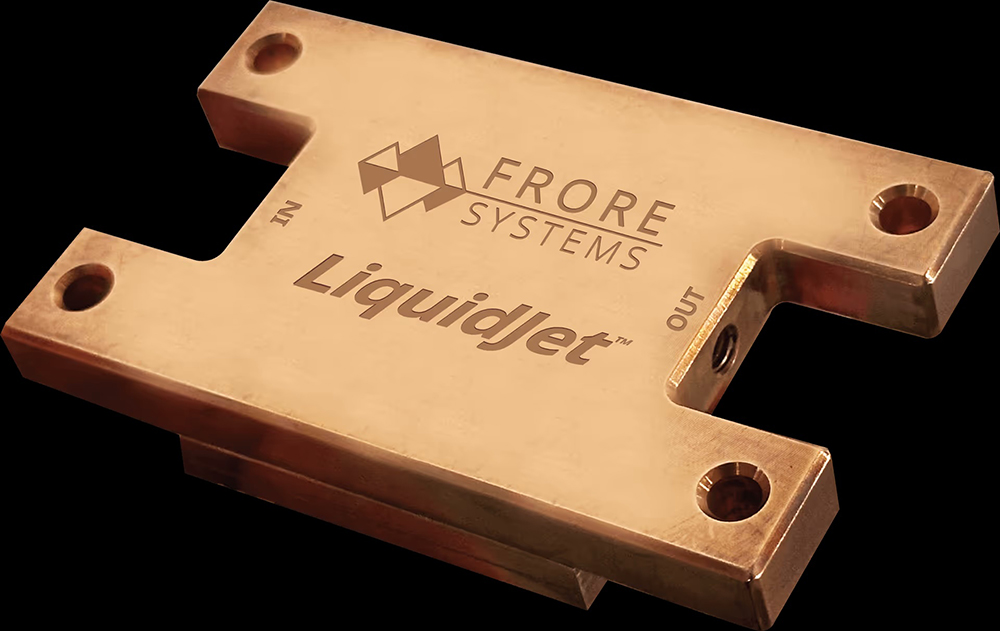

KAYTUS frames liquid-cooling deployment risk around tightly coupled parameters such as secondary-loop heat exchange efficiency, coolant purity, and end-to-end leak detection and monitoring. It also highlights the design and installation complexity of the liquid-cooling piping network, describing it as the thermal transport backbone and a major driver of schedule and implementation risk in large-scale deployments.

For prefabrication, KAYTUS says it factory-integrates and tests cabinet-level core components including liquid-cooled servers, quick disconnects, distribution and collection manifolds, and coolant distribution units (CDUs). It reports each cabinet undergoes standardized automated pre-validation tests including air-tightness testing, burn-in with coolant and power applied, intelligent drain and dry-out, and nitrogen-filled protection. On site, cabinets are connected to the data hall’s primary liquid-cooling loop through standardized interfaces, with KAYTUS claiming on-site installation time can drop from days to hours versus conventional methods.

KAYTUS also describes on-site customization and operational readiness work. For airflow management, it says its team performed on-site measurements and three-dimensional modeling to design per-row hot- and cold-aisle containment with high sealing performance to reduce hot and cold air mixing. For mechanical stability, KAYTUS says it engineered height-adjustable joining brackets and reinforced leveling feet to address minor floor unevenness. For piping, it reports using a multi-level pipeline stiffening and vibration-damping solution to support dense underfloor and overhead routing and to reduce the risk of interface loosening from sustained vibration.

On the software side, KAYTUS says it used its PODsys parallel deployment technology to install software simultaneously across multiple cabinets to keep the operating system kernel, drivers, and DOCA versions consistent. KAYTUS reports deployment of 20 cabinets and 360 nodes in 40 minutes, claiming more than 7.8× efficiency improvement over conventional node-by-node methods. For validation and tuning, it says it ran proof-of-concept testing on two cabinets covering hardware feasibility, system and software compatibility, performance achievement, and reliability validation, then expanded to network and performance stress testing at node, cabinet, and multi-cabinet levels. Based on results, KAYTUS says it tuned access paths, memory allocation mechanisms, I/O paths, and network protocol stacks, and reports a 20% performance lift versus bare-metal baseline in representative benchmarks including GEMM, NCCL, and LLaMA.

Source: KAYTUS