PCBAIR, a PCB manufacturer and assembly provider, has announced upgrades to its heavy-copper PCB manufacturing processes to address thermal management limits in next-generation AI servers and high-performance computing (HPC) clusters. PCBAIR says the updated process is designed to handle extreme power density and heat dissipation requirements as accelerator and graphics processing unit (GPU) power rises.

PCBAIR cites Thermal Design Power (TDP) for modern AI accelerators and GPUs that frequently exceeds 700 W per chip, pushing traditional printed circuit board (PCB) stack-ups toward electrical and thermal constraints. It notes that standard copper weights can be insufficient for high-current Power Delivery Networks (PDN), contributing to I²R losses and heat buildup. PCBAIR says its upgraded line supports heavy-copper fabrication up to 10 oz (approximately 350 µm) for both inner and outer layers, positioning the PCB to act as a heat spreader and reduce reliance on external cooling.

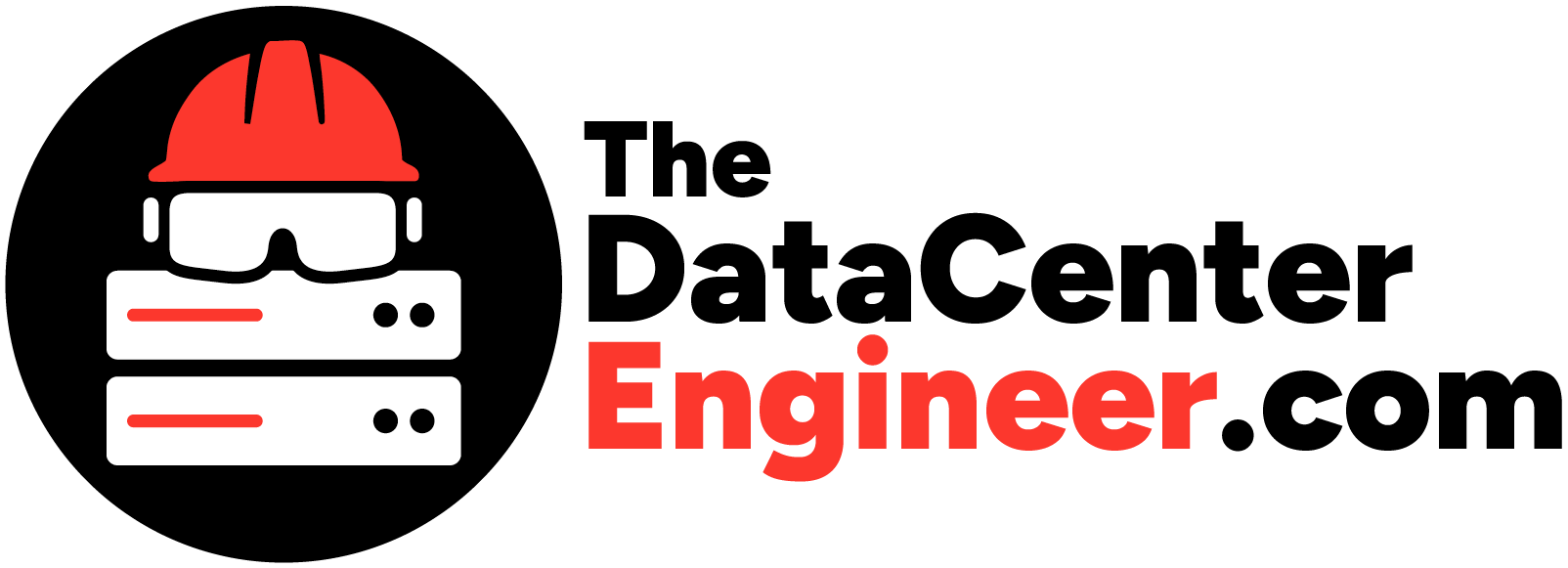

The company says the upgrade targets heavy-copper fabrication defects including undercutting (trace narrowing) and resin starvation during lamination. “The PCB has evolved from a passive carrier to an active component of the thermal solution,” said Victor Zhang, CTO of PCBAIR. “The real challenge with heavy copper isn’t just plating thickness; it is achieving straight sidewalls to ensure electrical performance.” “Our upgraded process utilizes advanced differential etching compensation and vacuum-assisted resin filling. This ensures we deliver the high-current capacity engineers need, eliminating the micro-voids or delamination risks that often affect thick-copper boards.”

PCBAIR lists several technical enhancements, including embedded copper coin technology that integrates solid copper “coins” into the PCB to create a vertical thermal path from hot components such as voltage regulators to the chassis, addressing the low thermal conductivity of FR-4 substrates. It also cites an optimized etching factor using proprietary chemical etching protocols to maintain trace-width consistency on 6 oz and higher layers, which PCBAIR says is important for stable impedance in power modules. PCBAIR also reports high-reliability material qualification for compatibility with high-glass-transition-temperature (high-Tg) laminates intended to withstand thermal cycling in data center environments.

For reliability validation, PCBAIR says it has implemented enhanced testing and that internal reports indicate heavy-copper prototypes passed 1,000 cycles of thermal shock testing from -40 C to +125 C with zero continuity failures, which it says validates plated-through-hole (PTH) and interconnect robustness. PCBAIR says it is accepting requests for quotation for prototyping and low-to-mid volume production, and it positions the capability as an expansion beyond consumer electronics to support infrastructure needs in AI and automotive markets.

Source: PCBAIR