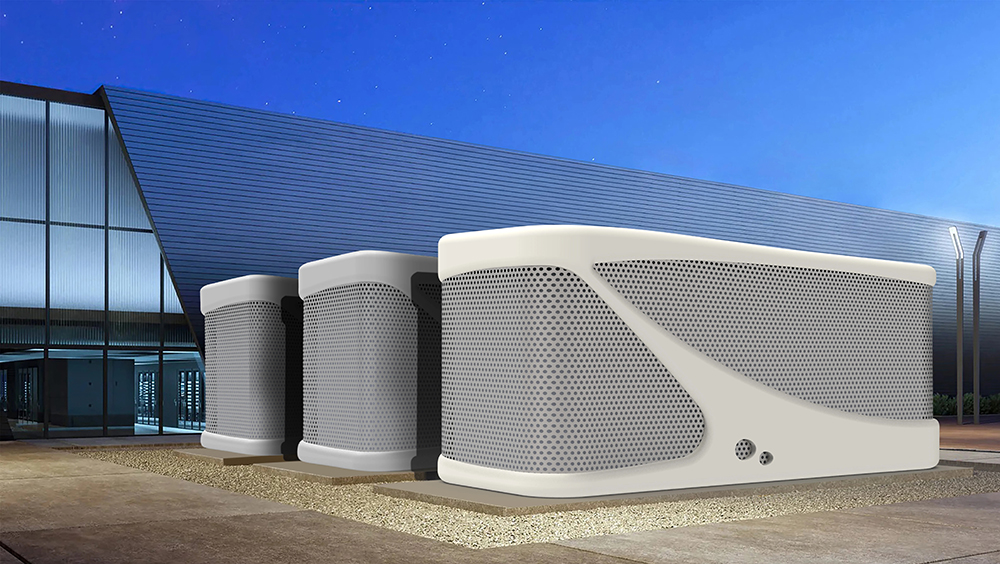

Karman Industries has announced the Heat Processing Unit (HPU), a modular 10 MW integrated thermal platform it says is designed to address “speed-to-power” constraints for AI hyperscale data centers. The company positions the HPU as a way to consolidate heat-management infrastructure into high-density modular packages, cut exterior mechanical-yard footprint by 60% to 80%, and eliminate water consumption.

Karman says traditional giga-scale designs can require “500+ disparate chillers and dry coolers,” along with “miles of complex piping” and “months of on-site assembly.” Its HPU approach is intended to reduce the number of units to install, pipe, and wire on-site, while enabling heat reuse for power generation or district heating.

Karman says HPUs “interact with the facility’s cooling and power streams” to optimize Power Utilization Effectiveness (PUE). The architecture is intended to work across locations and ambient conditions, including hot environments where it says HPUs can provide efficient cooling with “zero water consumption,” and cold environments where it says waste heat can be processed to provide electricity for operations or “high-grade heat for district heating.”

For data center systems requiring lower-temperature cooling loops—citing HBM4 (High Bandwidth Memory 4)—Karman says the HPU can repurpose high-temperature waste heat from GPU clusters (including NVIDIA Blackwell or Rubin platforms) into cooling at less than 30 °C.

“We applied an aerospace systems-engineering approach to data center thermodynamics,” said CJ Kalra, CTO and Co-Founder. “Our team designed HPUs to process the extreme heat of gigascale racks using a first principles based approach. HPUs enable heat reuse and PUE ratings quickly approaching 1 without water consumption or PFAS chemicals for AI factories. Keeping up with the latest in technology, the HPU leverages 800V DC architecture while borrowing the latest innovations in rocket turbomachinery like metal 3D-printing, and electric vehicles innovations like high-speed motors & Silicon-Carbide power electronics technology.”

Karman says it will begin initial customer deliveries in Q3 2026 from its Los Angeles-based GigaWerx manufacturing facility, which it says is designed for 1 GW of annual production with a roadmap to reach 4 GW annually.

Source: Karman Industries